How do I diagnose a fault?

Trouble Shooting Clutch Systems

Section #1 Noise

Noise while depressing clutch pedal

Cause

- Off centering of the release bearing or mis-alignment of the main shaft.

Repair

- Replace the release bearing.

- Realign the engine and the gear box.

Section #1 Loss of Drive

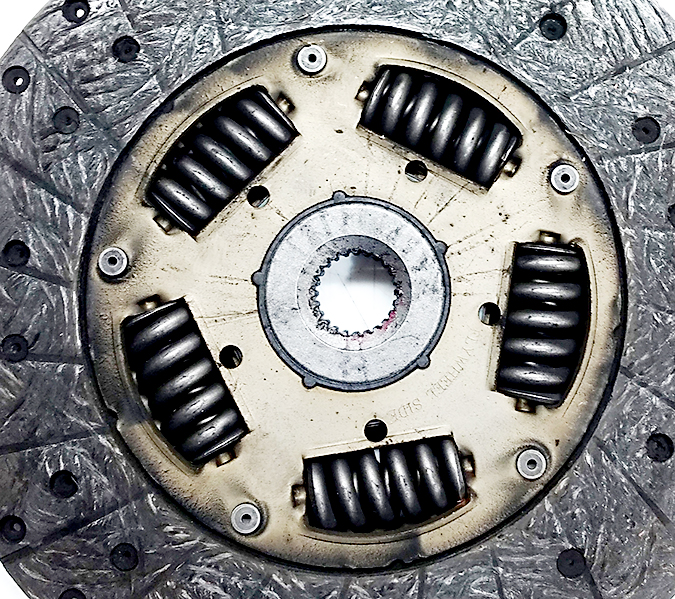

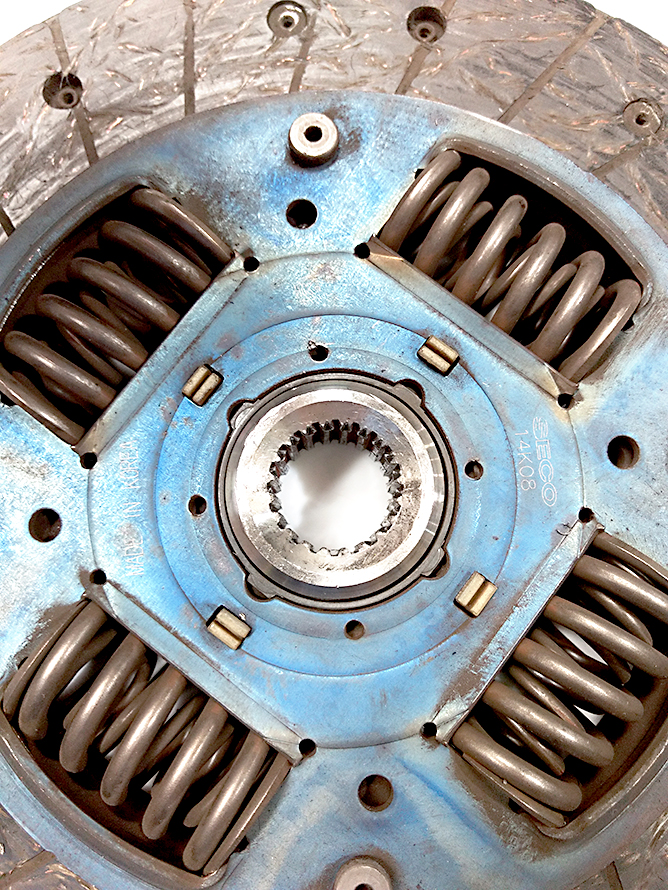

Cushion Plate broken

Cause

- The disc has been distorted when refitting the gear box on the engine.

- The engine and the gear box are misaligned.

- The pilot bearing is damaged.

- Aggressive driving.

Repair

- Replace the clutch kit.

- Realign the engine and the gear box.

- Replace the pilot bearing.

Caution

- Be careful in selecting the gears and do not over run the clutch.

Clutch disc plate broken

Cause

- Defective clutch installed or wrong direction for installation.

Caution

- Make sure that the correct kit is used on the application.

Section #2 Noise

Noise when in neutral

Cause

- Lack of care during installation, splines have been damaged by the gear box main shaft.

Repair

- Replace the main shaft.

- Replace the clutch disc.

Caution

- Make sure that the splines properly match up.

- Lubricate with a proper quantity of grease.

Noise during release

Cause

- Seized / worn pilot bearing / bushing.

Caution

- Replace pilot bearing / bushing.

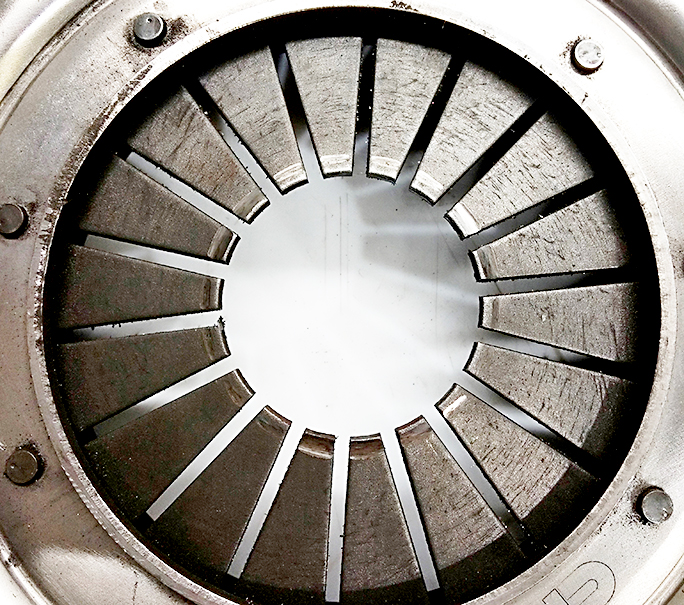

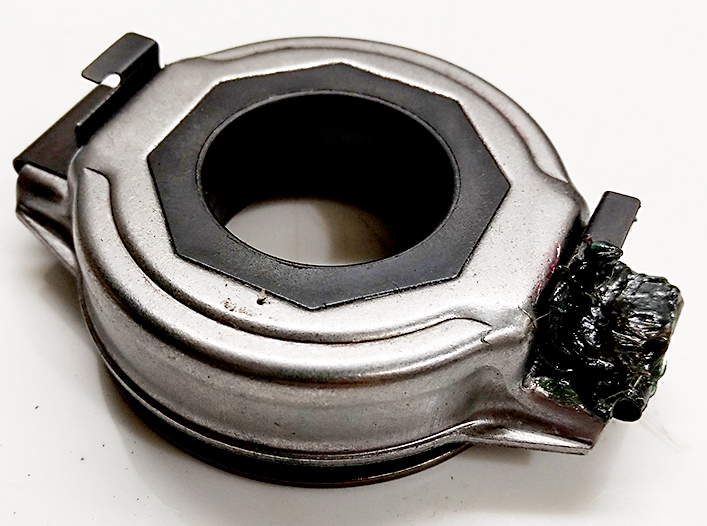

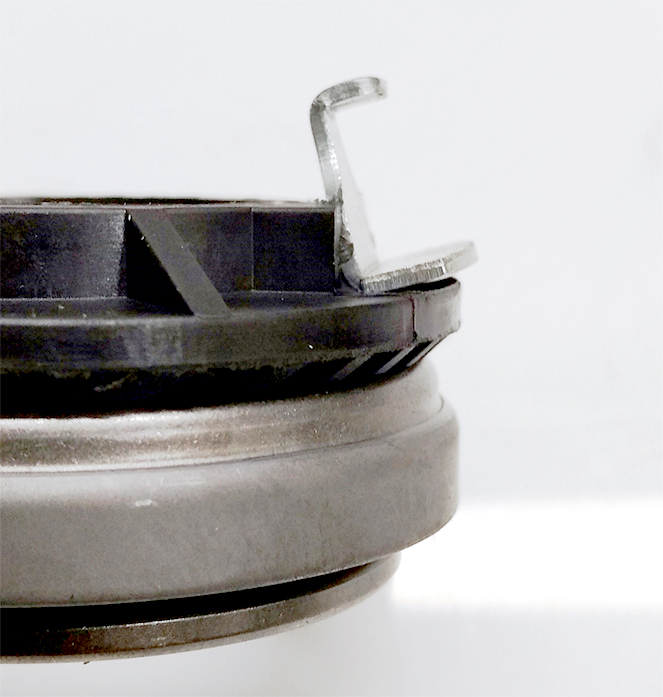

Release bearing damaged

Cause

- Seal torn.

-

Overheating during slippage.

Leakage of the grease.

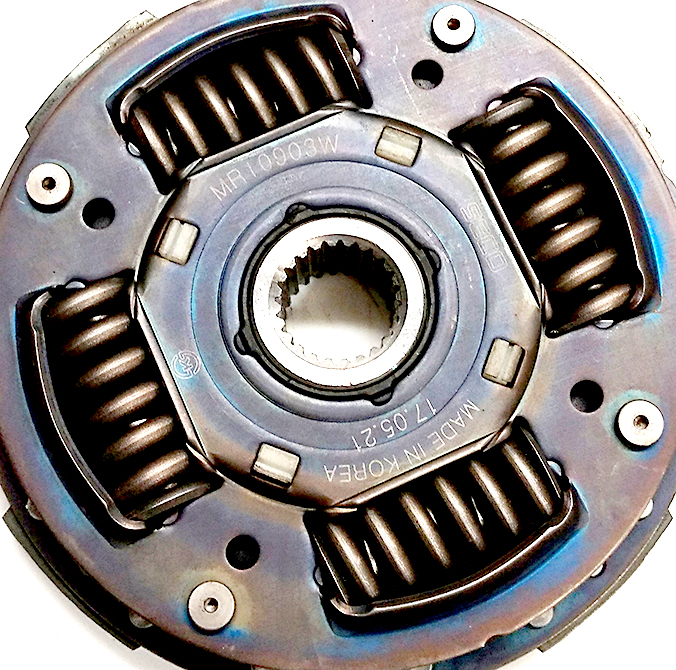

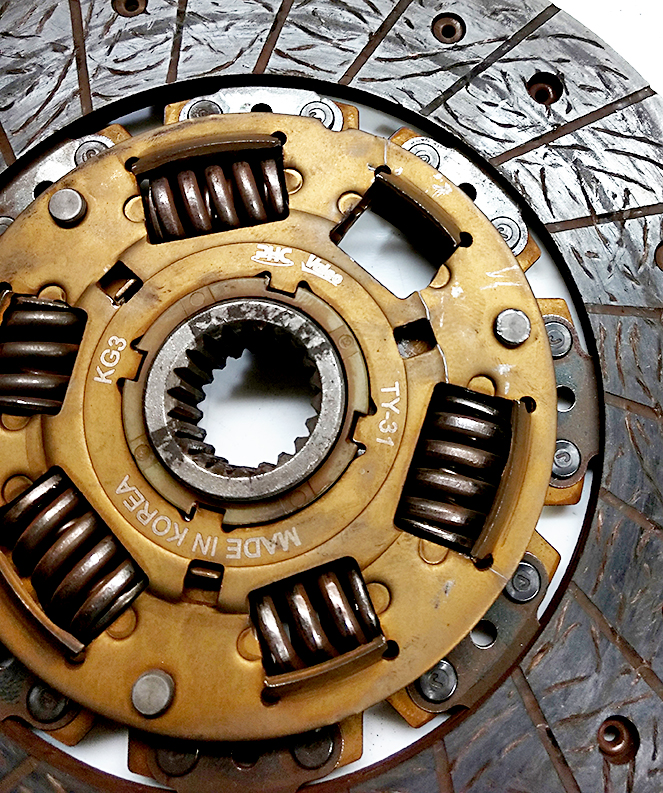

Damper spring break away

Cause

- Wrong clutch cover size used.

- Excessive release travel.

- The clutch disc is installed on the wrong side.

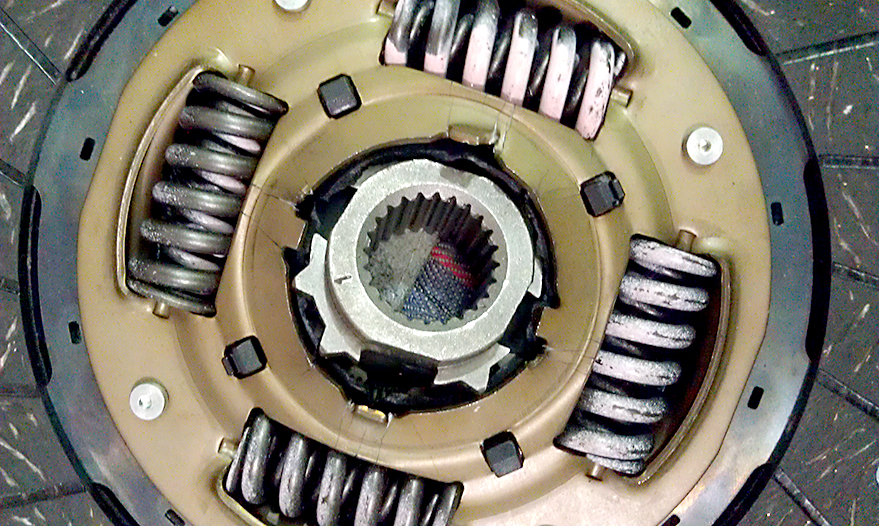

Unusual worn out on the torsion spring area

Cause

- Over torque applied to the clutch disc.

Section #3 Slipping

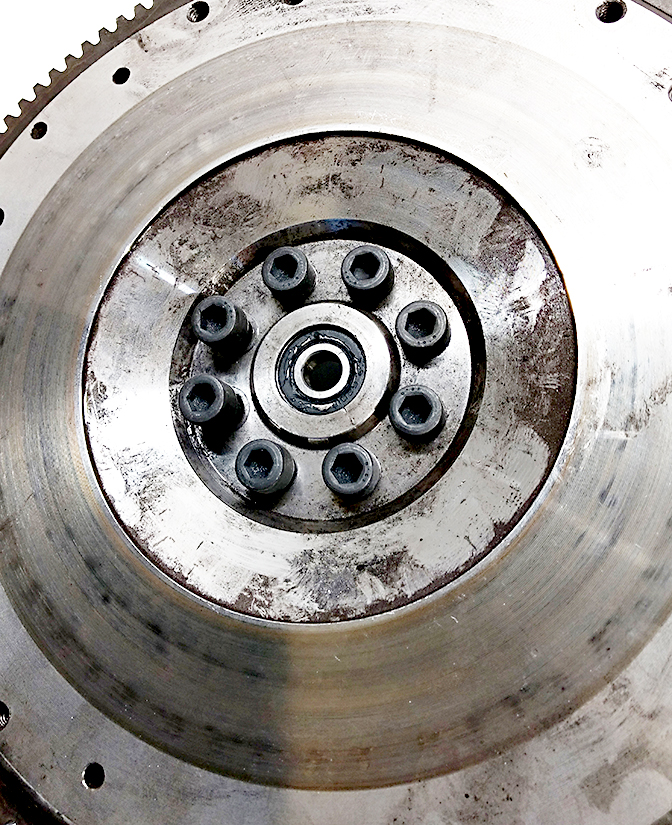

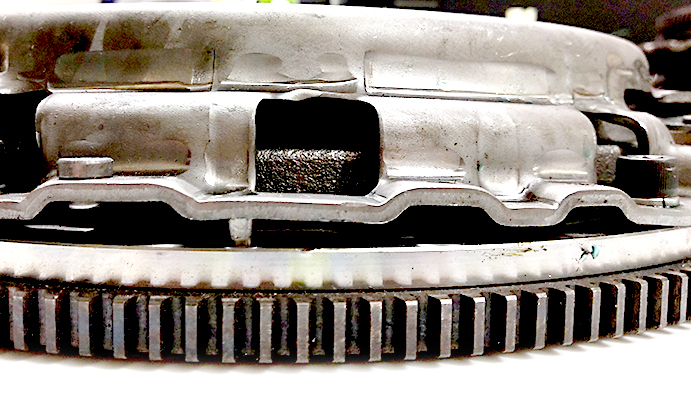

Burn marks on the flywheel

Cause

- Excessive greasing of the spline hub when installed.

Repair

- Clean the flywheel and replace the clutch disc.

Caution

- Apply the correct amount of grease on the clutch disc splines and the input shaft

Section #3 Slipping & Chattering

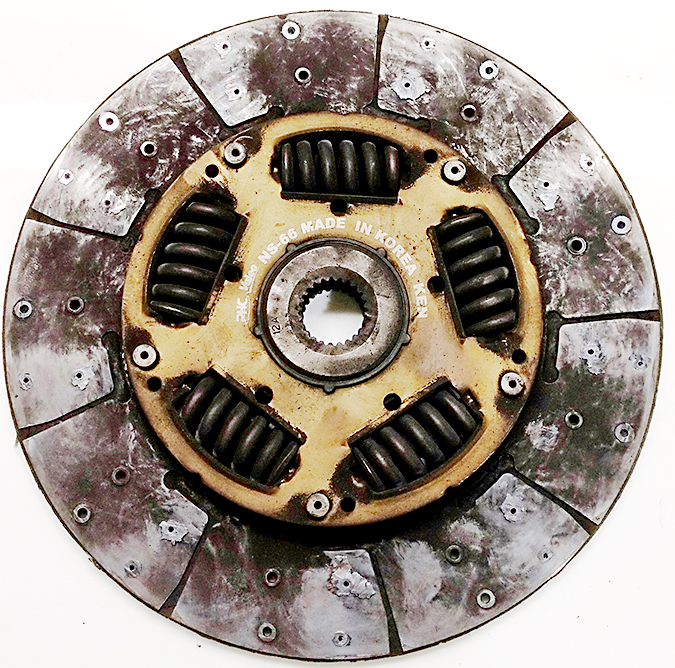

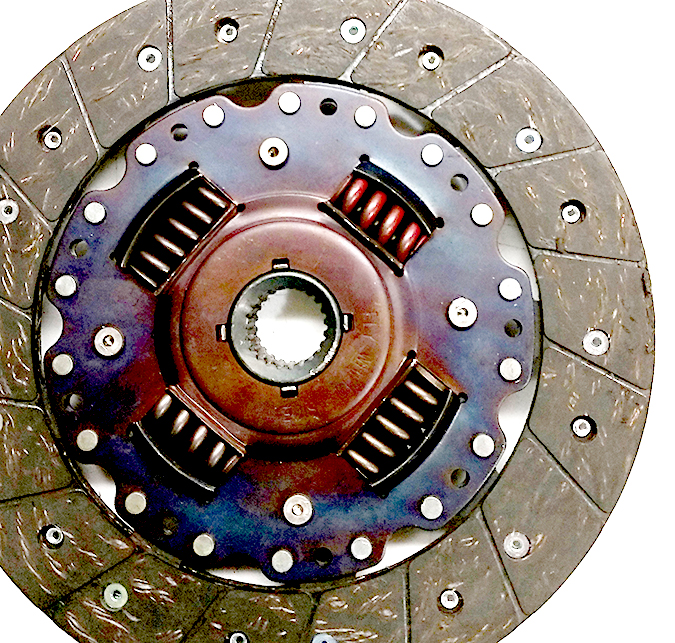

Clutch facing completely worn

Cause

- Use over product lifetime.

- Prolonged clutch slippage due to a malfunction or extremely severe use. Disc not changed during a previous flywheel / cover replacement.

Clutch lining damaged

Cause

- Excessive slippage due to aggressive driving or overloading.

- The clutch operating system is badly adjusted or defective.

Repair

- Replace the clutch kit.

- Replace or machine evenly the flywheel.

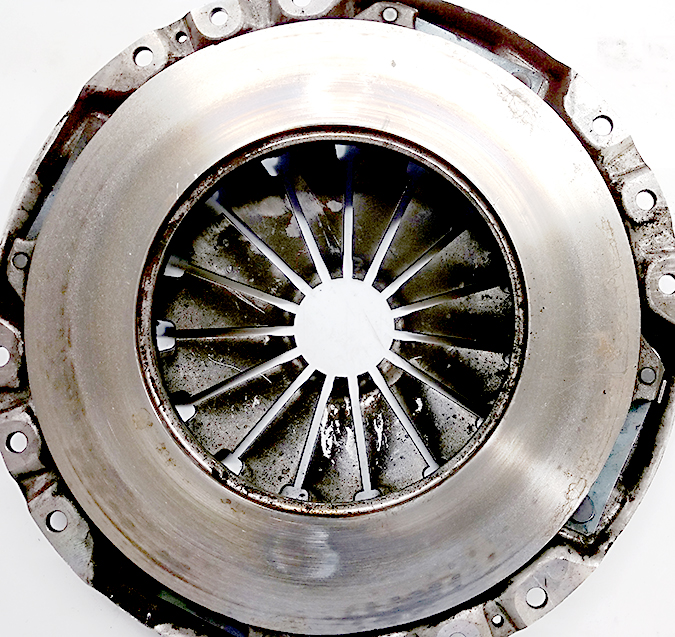

Burn marks on the pressure plate

Cause

- Oil or grease contamination on the clutch linings or on the pressure plate.

Repair

- Locate and repair all sources of contamination.

- Replace the clutch kit.

Caution

- Apply the correct quantity of grease on the clutch disc splines and the input shaft. Do not use contaminated pair of gloves.

Circular grooves appearing on the pressure plate

Cause

- Linings worn out, heads of the facing rivets are in contact with the pressure place.

Clutch lining contaminated with oil or grease

Cause

- Excessive greasing of the spline hub when installed.

- Oil leakage from engine or gear box.

Repair

- Replace the clutch disc.

- Locate and repair all sources of contamination.

Caution

- Apply the correct amount of grease on the clutch disc splines and the input shaft.

Deformation of the clutch disc

Cause

- Deformed during delivery or handling.

- Deformed during installation. (weight of the gear box, dropped)

- Deformation due to overheating during slippage.

Caution

- Handle with care.

- Do not place the clutch disc under a weight.

Section #4 Difficulty changing gears

Difficulty changing gears

Cause

- The cover assembly has been dropped.

Repair

- Install new clutch.

- Always inspect the drive straps for damage before installation.

The drive straps of the clutch cover are damaged

Cause

- Dropped during installation / overload.

- Using improper product.

- Improper gear selection. (ex: from 5th to 1st)

Repair

- Replace the clutch disc.

- Careful handling.

- Operate to normal conditions.

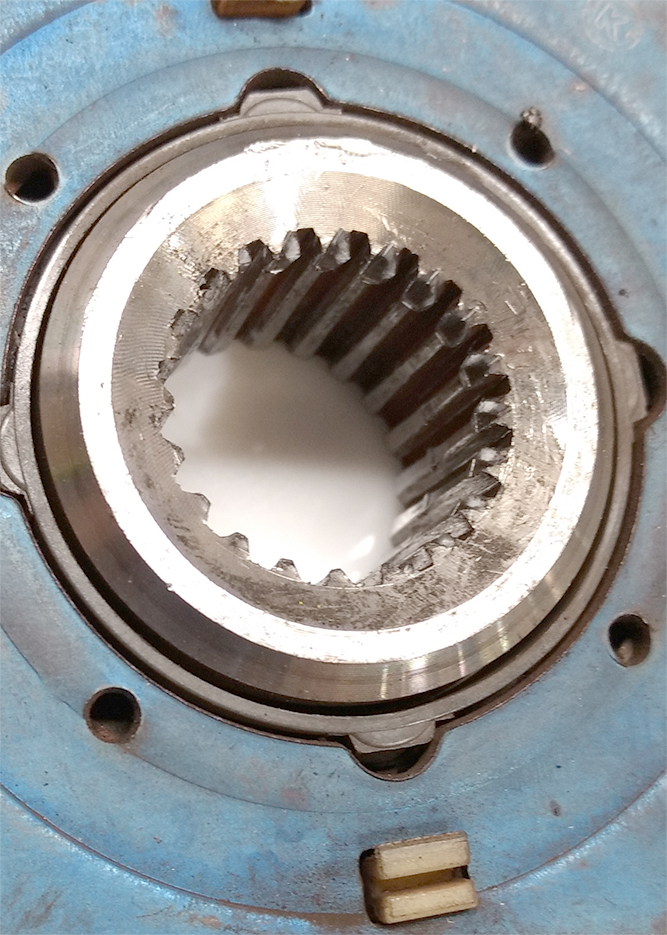

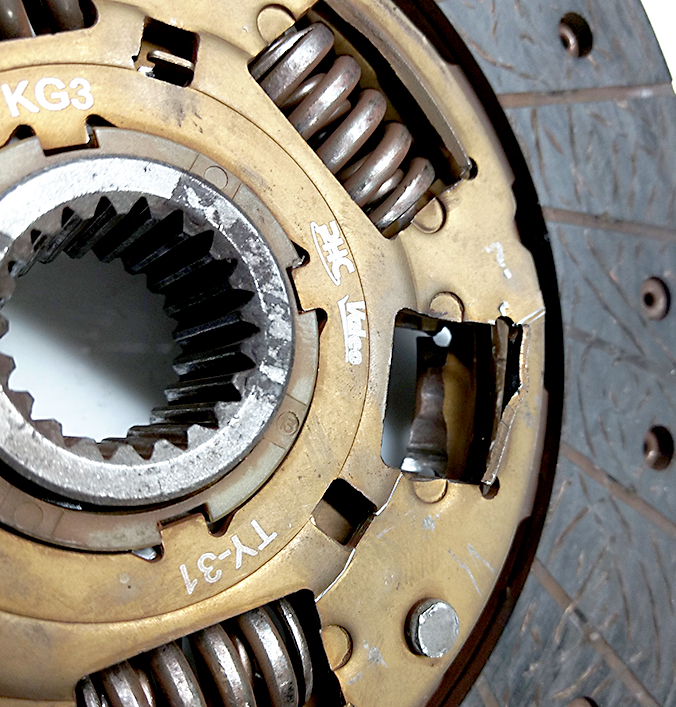

Difficulty changing gears

Cause

- The transmission was forced into position damaging the splines of the disc hub.

Repair

- Install new clutch and carefully control the position and alignment of the transmission during installation.

- Use a transmission jack and possibly install temporary guide pins to assist in aligning the transmission to the engine.

Section #5 Others

Too much grease

Cause

- Excess of lubrication grease on the nose of the release bearing.

Repair

- Clean the release bearing.

- Apply the correct quantity of lubricant.

Over torque

Cause

- Excessive engine brake operation.

- Incorrect disc for the application.

- Aggressive starting operation.

- The clutch operating system is badly adjusted or defective (clutch pedal)

Repair

- Replace the clutch disc.

Difficulty shifting

Cause

- Incorrect release bearing travel.

- The clutch operating system is badly adjusted or defective.

- The level of pre-load on the release bearing is incorrect.

Repair

- Adjust the clutch operating system (pedal height, self adjusting system, clutch linkage..) check the pre-load on the release bearing.

Clutch pedal binding

Cause

- The fork is out of shape.

- The release bearing guide tube is worn or the release arm / fork is bent / worn.

Repair

- Replace by a genuine release fork.

- Install new clutch and guide tube.

- Inspect all release bearing system components and repair or replace as needed.

The contact point of the fork is worn out, the fork is off-centered

Cause

- The fork is out of shape.

Repair

- Replace by a genuine release fork.